For nearly a decade, Silicon Valley's mantra has been clear: dematerialize everything. Transform atoms into bits. Move fast and break things, but preferably break them in code where the damage is reversible. This philosophy gave us streaming services, cloud computing, and mobile apps that transformed how we communicate, work, and entertain ourselves.

But 2025 marks an inflection point. The most ambitious technological ventures are no longer content to live behind screens. They're returning to the messy, unforgiving world of physics, and the results are nothing short of revolutionary.

The Speed of Electricity

Consider what just happened on a German test track. An all electric hypercar shattered the production car speed record, reaching 308.4 mph. This wasn't just an incremental improvement; it represented a fundamental reimagining of what's possible when you combine cutting edge battery chemistry with sophisticated power management.

The achievement required solving problems that software alone could never address: managing heat dissipation at extreme speeds, creating batteries that can discharge at rates ten times higher than conventional systems, and building motors that can deliver nearly 3,000 combined horsepower without thermal failure. This is engineering at the absolute edge of material science.

What made this possible? A 1200 volt ultra high voltage platform, proprietary blade battery technology, and perhaps most importantly, the unique characteristics of electric powertrains that allow for smooth, consistent power delivery impossible with traditional combustion engines. The test driver noted that the quiet, vibration free experience allowed for a level of focus and control previously unattainable at such speeds.

The Trillion Dollar Challenge of Dexterous Manipulation

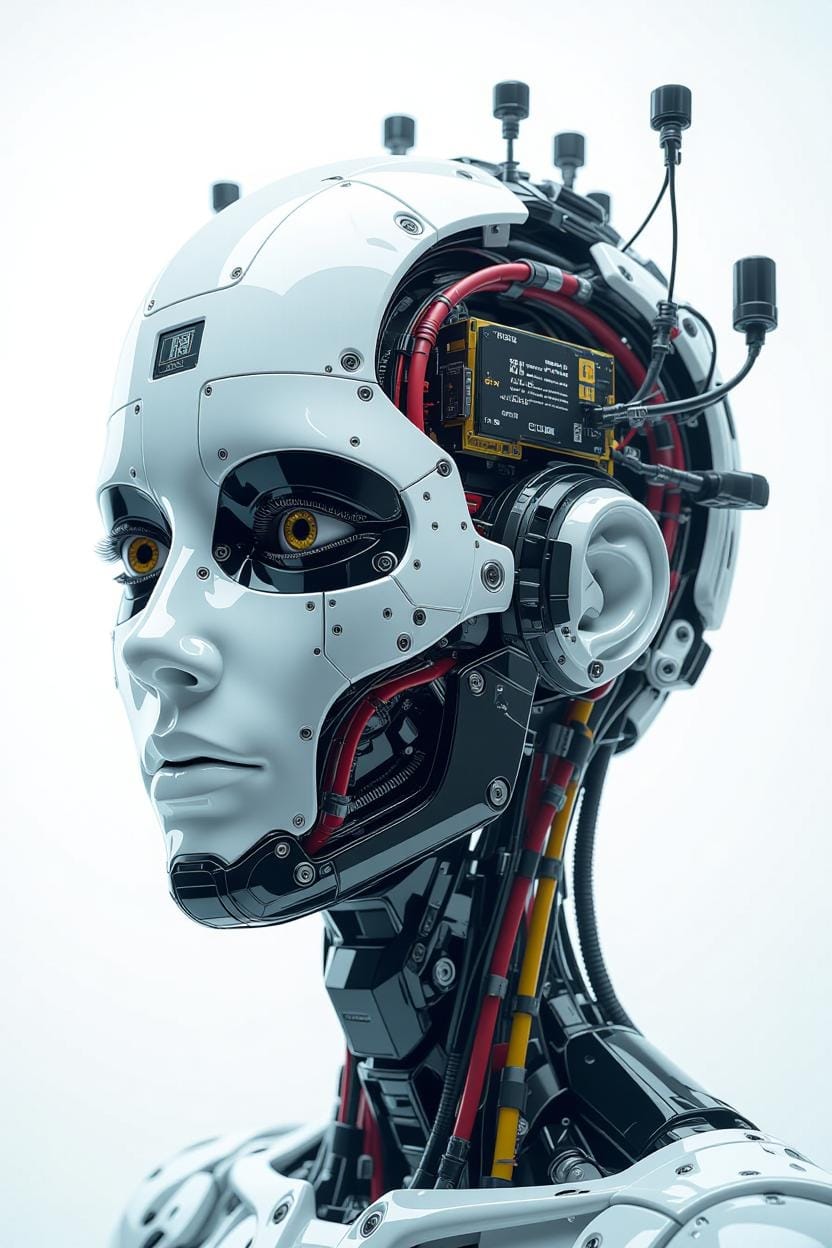

While speed records capture headlines, an even more profound transformation is happening in robotics. Major technology companies are making investments described as comparable in scale to the entire augmented reality market, potentially reaching hundreds of billions over the next decade.

The surprising truth about humanoid robotics is that walking isn't the hard part anymore. Companies have largely solved locomotion; robots can walk, run, and even perform backflips. The grand challenge lies in something far more subtle: dexterous manipulation.

Think about the last time you picked up a glass of water. Your brain performed countless calculations instantaneously: estimating weight, adjusting grip pressure, predicting liquid dynamics, compensating for movement. This seemingly simple act represents one of the most complex challenges in robotics today.

Solving it requires more than clever algorithms. It demands unprecedented integration of advanced sensors, fine motor control, and sophisticated AI models that can simulate and predict real world physics in real time. The goal for many isn't to manufacture robots at scale, but to develop the foundational software backbone that could become the operating system for an entire ecosystem of physical AI systems.

The New Engineering Renaissance

This return to physical innovation signals something profound about where technology is heading. After years of relatively frictionless digital innovation, the industry is tackling problems that can't be solved with code alone. These challenges demand a new generation of engineers who are equally comfortable with neural networks and Newtonian mechanics.

Consider what this means for the problems we can now address:

Manufacturing processes that adapt in real time to material variations. Transportation systems that push the boundaries of energy efficiency while delivering unprecedented performance. Robots that can work alongside humans in unpredictable environments, handling delicate tasks that were previously impossible to automate.

The Convergence Point

What makes this moment unique is the convergence of capabilities that were previously developing in isolation. Advanced AI provides the intelligence. Breakthrough battery technology provides the power. Sophisticated sensors provide the perception. Novel materials provide the structure. Together, they're enabling solutions to problems we couldn't even properly frame a decade ago.

This isn't about choosing between digital and physical innovation; it's about their synthesis. The electric hypercar wouldn't be possible without sophisticated software controlling every aspect of power delivery. The humanoid robot is essentially a physical platform for artificial intelligence to interact with the world.

What This Means for the Future

The return to atoms doesn't diminish the importance of bits; it amplifies it. Every physical innovation requires increasingly sophisticated digital twins, simulations, and control systems. The difference is that now these digital capabilities must grapple with the unforgiving constraints of the physical world.

For organizations and individuals, this shift presents both challenges and opportunities. Companies that have focused purely on software may find themselves needing to develop hardware expertise or forge new partnerships. Engineers who can bridge the digital physical divide will become increasingly valuable. And problems that seemed intractable when approached from either domain alone may suddenly become solvable through their integration.

The revenge of the physical is really the beginning of a new synthesis. We're not abandoning the digital revolution; we're extending it into dimensions that actually push back. And in that resistance, in that friction with reality, we're discovering possibilities that pure software could never achieve alone.

The future of technology isn't just getting physical again. It's getting real in ways we're only beginning to imagine.